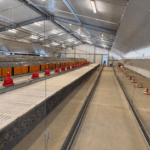

In Togo, Soproda has just completed the full equipping of a 90 m x 15 m broiler breeder building, designed to house 7,500 females and 1,250 males. This project is a concrete example of our expertise : combining high-performance, sustainable equipment adapted to local climatic conditions, while simplifying day-to-day management for the farmer.

Breeding broilers requires precise control of feed, hydration, ventilation and temperature. In this project, each piece of equipment has been carefully selected to ensure optimal long-term reliability, maximise animal performance and reduce operating costs.

How does modern equipment increase farm performance?

✔️ Feeding circuits for females : Three suspended feeding circuits equipped with Champion chains ensure even distribution to all females. The suspension allows the height to be adjusted according to age or growth, reducing competition between animals and avoiding waste. Automation ensures accurate and regular feeding, while reducing the farmer’s workload.

✔️ Male Pan feeding trays for males : Two rows of suspended Male Pan trays ensure exclusive distribution for males. Robust, easy to clean and adjustable, this equipment prevents the ingestion of feed intended for females, allowing precise ration control and better growth management.

✔️ Plasson Mark II automatic drinkers : Plasson Mark II drinkers guarantee a constant supply of clean water, limit waste and prevent puddles from forming. Their sturdy design is ideal for breeding stock, ensuring optimal hygiene.

✔️ FW-99 scale : For accurate monitoring, the FW-99 scale measures the exact amount of feed distributed each day. With its digital display and built-in memory, it allows the farmer to quickly detect any anomalies and optimise consumption.

✔️ Tunnel ventilation with Pad Cooling : Tropical climates require strict temperature and humidity control. We have therefore installed a tunnel ventilation system, combining powerful extractors and evaporative cooling panels (Pad Cooling). The result: a stable indoor climate, reduced heat stress and regular egg laying.

✔️ Jet MASTER heating : For cooler periods or when starting batches, the Jet MASTER ensures rapid and uniform temperature rise. Its adjustable power optimises energy consumption while ensuring the vitality of the chicks.

✔️ VIPER Touch computer : The VIPER Touch is the building’s command centre, managing all parameters : feeding, watering, ventilation and heating. Its intuitive touchscreen interface offers centralised control, customised settings and detailed monitoring of all rearing parameters.

Why is this type of installation an asset for Togolese farmers?

Designed to withstand the demanding climatic conditions in Togo, this installation guarantees precise temperature and humidity control throughout the year. This helps maintain a stable and comfortable environment for the animals.

The automation of the systems greatly reduces the need for manual intervention, saving you valuable time while reducing labour requirements. In addition, the robustness of the equipment ensures reliable operation even under intensive use.

By creating optimal breeding conditions, this type of facility improves both the health and productivity of your animals. This translates into increased profitability, thanks to reduced losses due to disease or excessive heat, and better control of your production costs.

Soproda’s expertise at the service of your projects

With over 30 years of experience in Africa, Soproda supports farmers from start to finish. We provide advice and precise sizing of facilities, supply high-end poultry equipment as well as handle the assembly and commissioning of your project. Our technical support and after-sales service also guarantee the optimal long-term operation of your equipment.

Do you have a poultry project in Togo or elsewhere in Africa?

📞 Contact us now to discuss your objectives and find out how Soproda can help you !

#PoultryFarming #Togo #Soproda #BigDutchman