A Typical Industrial Project

Soproda supports you at every stage of your poultry project, from initial analysis to building commissioning. Our methodology is based on an in-depth understanding of your needs, the precise design of appropriate solutions and the supply of high-performance equipment. Whether you’re looking to modernize, optimize or expand your operation, we can offer you a turnkey solution, including complete installation for an efficient start-up. Explore each stage of a typical project and discover how we can turn your ambitions into tangible success.

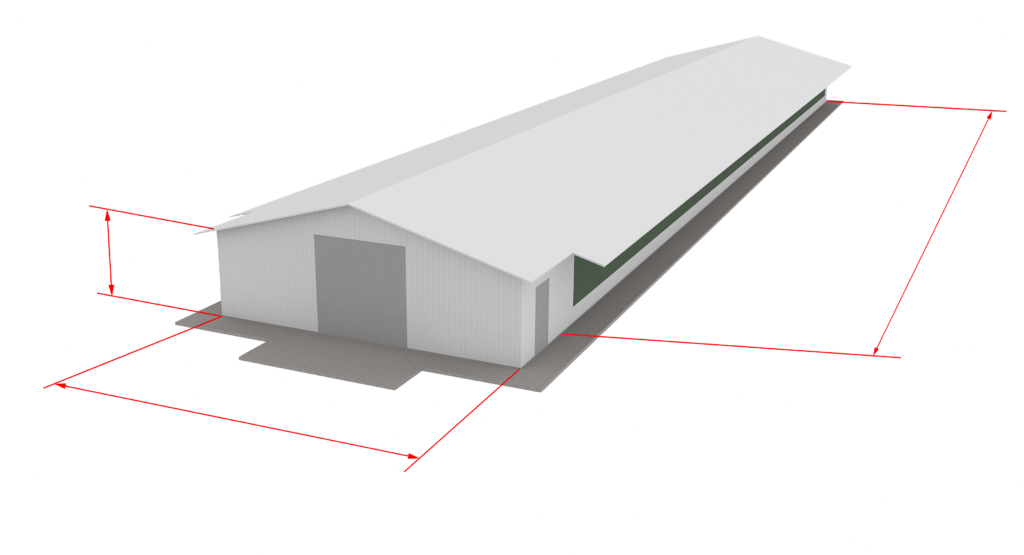

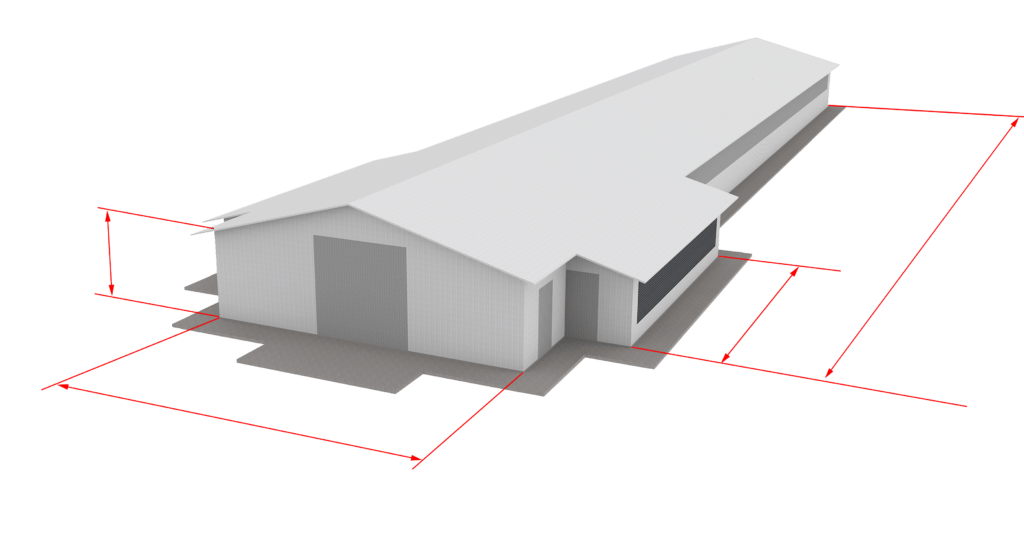

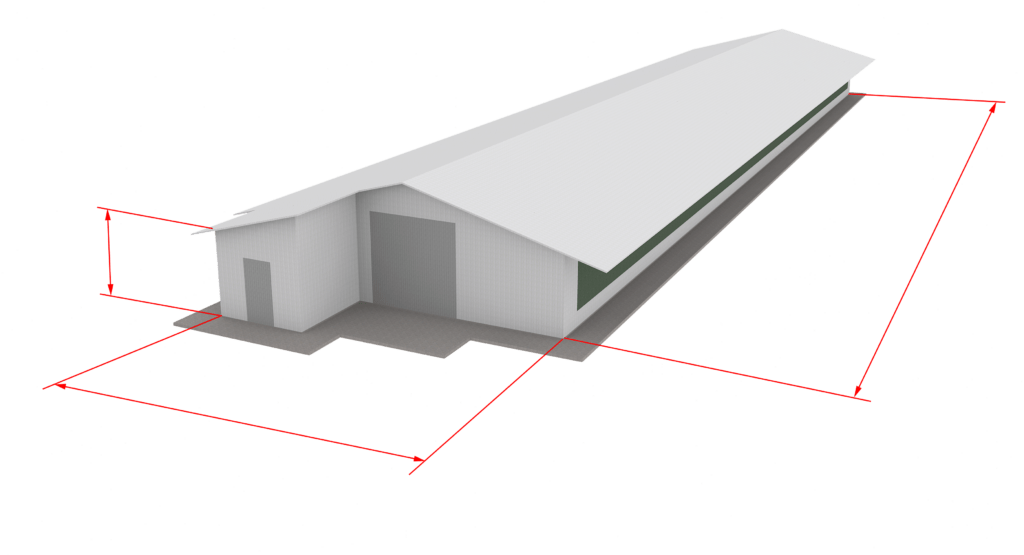

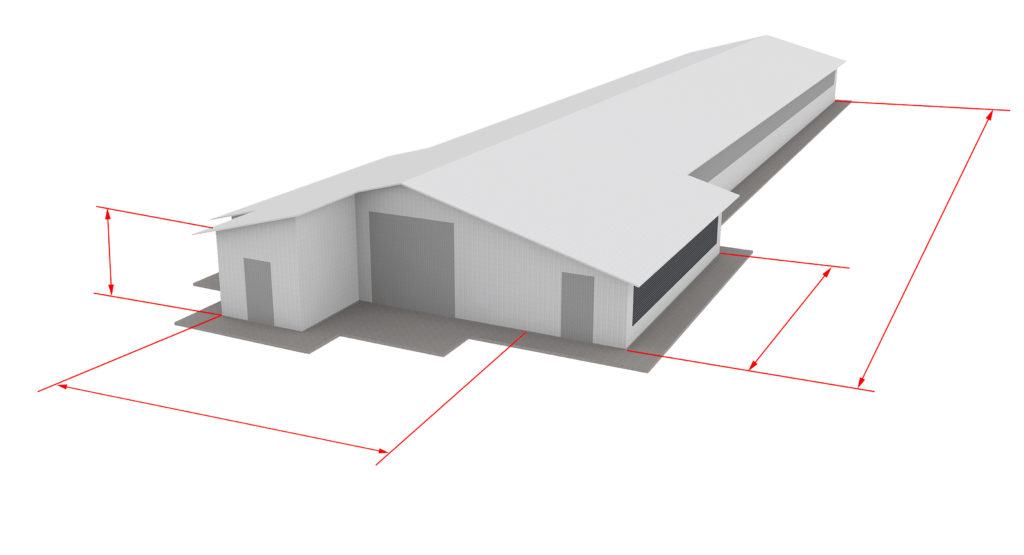

How to Design an Efficient Poultry Building ?

A high-performance poultry building is based on a tailor-made design, combining quality materials and advanced technologies. It must guarantee an optimal environment for the animals, ensure efficient production management and reduce energy costs. At Soproda, we design sustainable infrastructures adapted to each farm, taking into account local and climatic constraints. Discover how our buildings make a difference :

How Does Soproda Ensure the Success of Your Project ?

We have developed a structured four-stage process to ensure the success of your poultry operation, from conception to commissioning. Each phase is carefully designed to meet your requirements, with tailor-made solutions for each key step of your project. Find out how we guide you along the way :

Product discovery

The first step is to explore our wide range of products and identify the equipment that interests you. Our online shop gives you an overview of all our available solutions, whether for hatching, rearing, feeding, packaging, slaughtering or other purposes.

First contact

Once you’ve defined your project, contact us. You can select the products you want and request a quote from your shopping basket, or contact us via our online contact form. Our telephone switchboard is also at your disposal on +33 1 64 20 94 40 to answer any questions you may have.

Analysis of your needs

To discuss your requirements in detail, we’ll arrange a meeting. This meeting can take place in our offices, by videoconference or during our regular visits to Africa or the French overseas departments and territories. Together, we’ll define the most appropriate solution for your resources and constraints.

Drawing up an initial quotation

Once we’ve identified your needs, our team will draw up a detailed initial quotation to provide you with a transparent and comprehensive offer. This document includes all essential information, such as product descriptions, quantities and associated prices. This initial quotation forms the basis of our future discussions and is designed to give you a clear idea of what we can do for your poultry project.

Returns and quote adjustments

Once we’ve received your quotation, we encourage you to give us any feedback you may have. Whether it’s a change in quantity, an additional option or product adjustments, we revise the quotation until it perfectly meets your expectations. This iterative process ensures that you have total control over your order, ensuring that all your requirements are taken into account.

Order validation

Once you’re happy with the final quote, we begin the order validation process. This essential step marks the official start of our collaboration and ensures that all agreed conditions are fully understood and accepted by both parties. To proceed, please return the duly signed quotation to us. On receipt of this document, we will send you an order confirmation by e-mail.

Order payment

Once the quotation has been validated, we will send you an invoice for payment of your order. You’ll find all the information you need, including our bank details and payment methods, to make this payment in complete security.

Order schedule

So that you can anticipate future deliveries, we send you a detailed schedule that includes all the key stages of your project and estimated lead times. This schedule gives you an overview of the process, so you can prepare for the arrival and installation of your equipment.

Packaging and delivery

Before shipment, each item in your order is carefully prepared and packed to ensure that it arrives in perfect condition. Shipping is carried out in accordance with the details on the quotation and schedule. Should any unforeseen circumstances arise, we promise to keep you informed, ensuring total transparency.

Receiving your order

Before your order arrives, we prepare and send you all the necessary shipping documents. This includes the loading slip, commercial invoice, packing list, certificates of analysis and other required documents. These are crucial for customs clearance and the smooth receipt of your goods.

Equipment installation

Our team visits your site to install the equipment and ensure that each piece of equipment is correctly configured. This step is essential to ensure that all components are ready for safe and efficient use, enabling you to start your operation with confidence.

After-sales service

We are always available to provide after-sales service for your equipment. Whether you need technical adjustments, operating advice or answers to your questions, we can provide you with top-quality after-sales service. Don’t hesitate to contact us at any time – we’re here to support you over the long term.

An Example That Illustrates Our Skills

Successful transformation in Mayotte

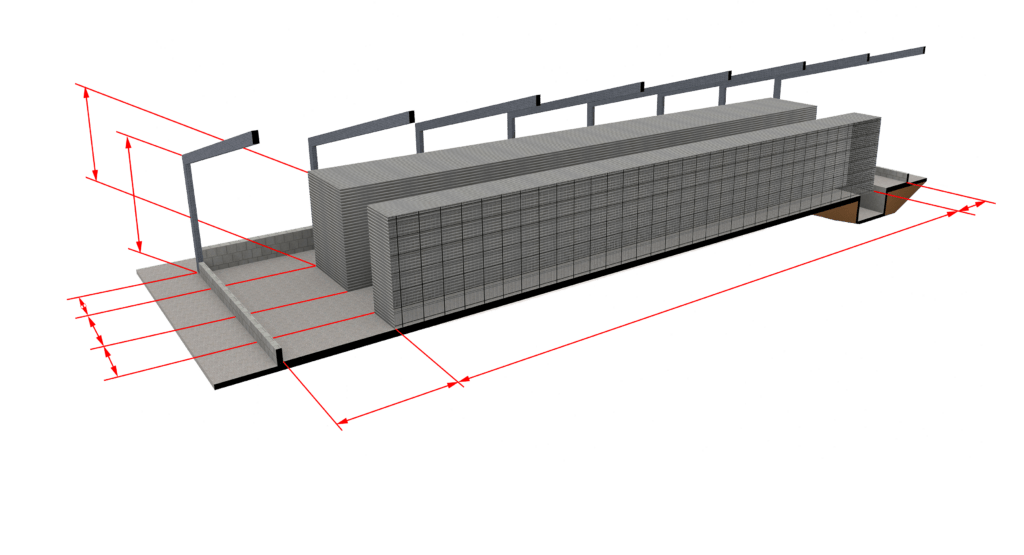

Superb renovation work carried out for one of our customers in Mayotte. We modernized an old Eurovent battery system into a modern 2-storey aviary capable of housing 25,000 layers. Thanks to the exceptional quality of Big Dutchman equipment, even after 5 years of use, the installation is as good as new! Visit our News page to see more examples of our work and how we help our customers achieve their goals.