For All Your Slaughtering Projects

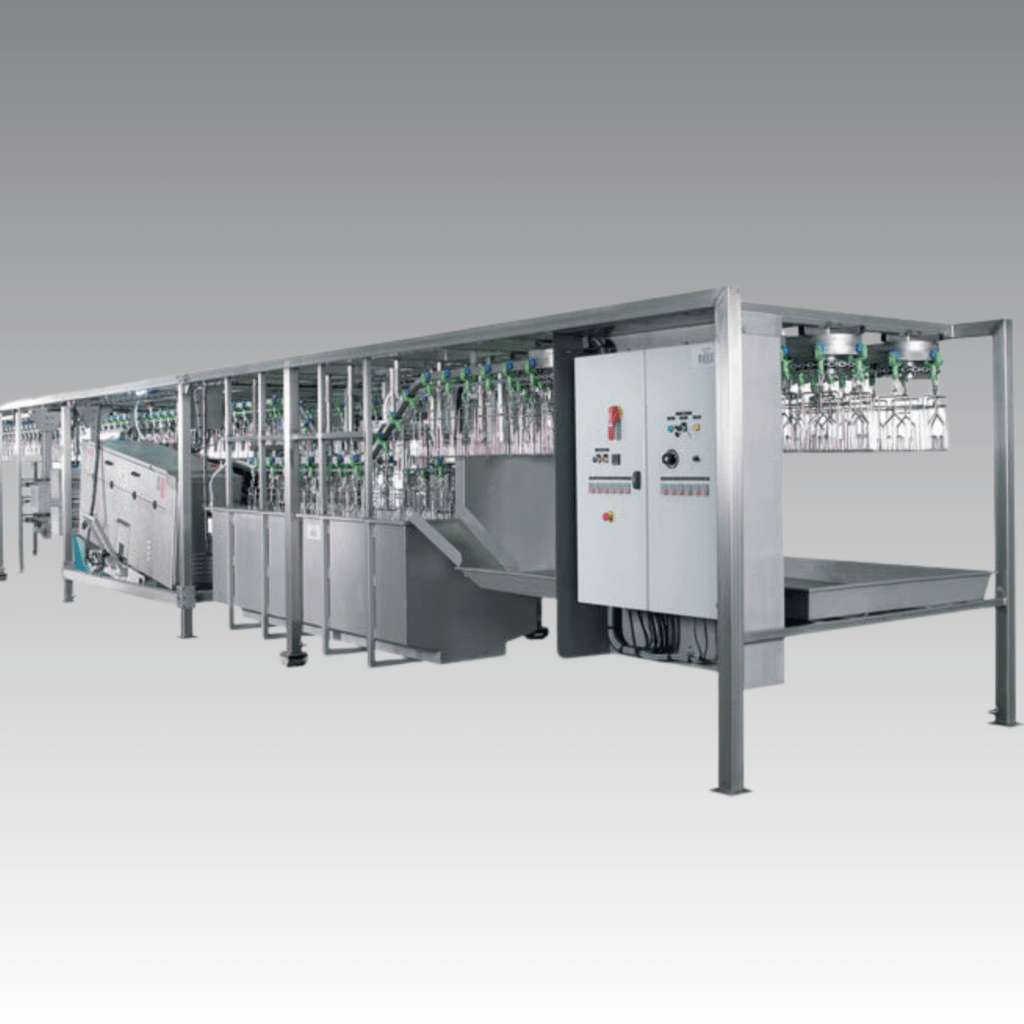

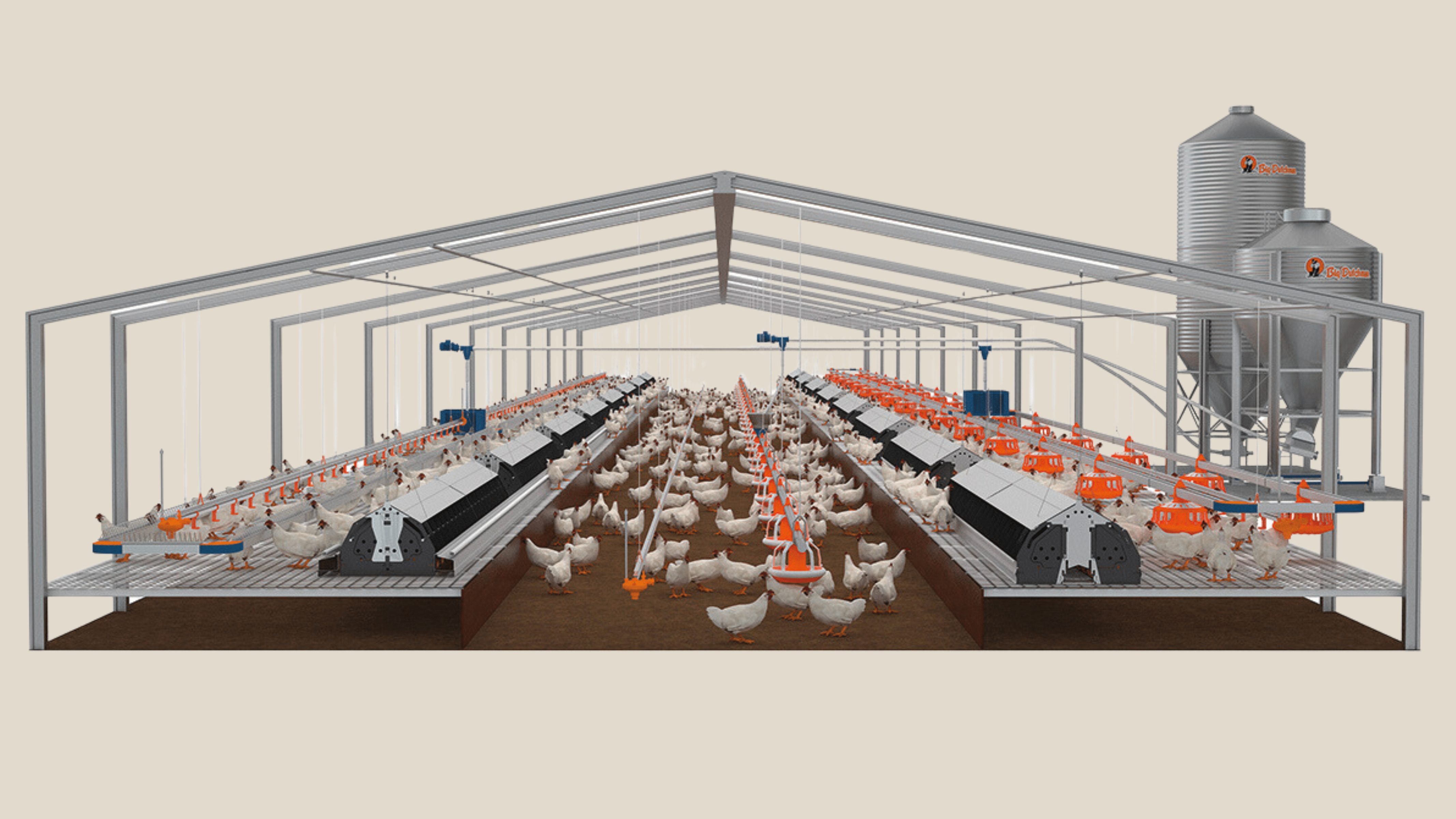

Since 1989, Soproda has played a major role in poultry farming and slaughtering equipment. We provide professionals with reliable, durable equipment designed to meet the specific requirements of their activity. Our products are designed to provide optimum working comfort while guaranteeing impeccable processing quality.

Why Entrust Us with the Construction of Your Slaughterhouse ?

Efficiency

Durability

Adaptability

Our complete range, from slaughter tables to smoking solutions, is designed to meet all your poultry processing needs. With our equipment, you benefit from the following advantages :

–Maximum efficiency : Our equipment is designed to speed up the slaughter process while maintaining high standards of precision and safety.

–Robustness and durability : Each product is manufactured using high-quality materials, guaranteeing performance and longevity even in demanding environments.

–Optimised hygiene : Our specialised solutions ensure that poultry is processed in clean conditions that comply with international health standards.

–Flexibility and adaptability : Our diversified range can meet your specific needs and adapt to all types of production.

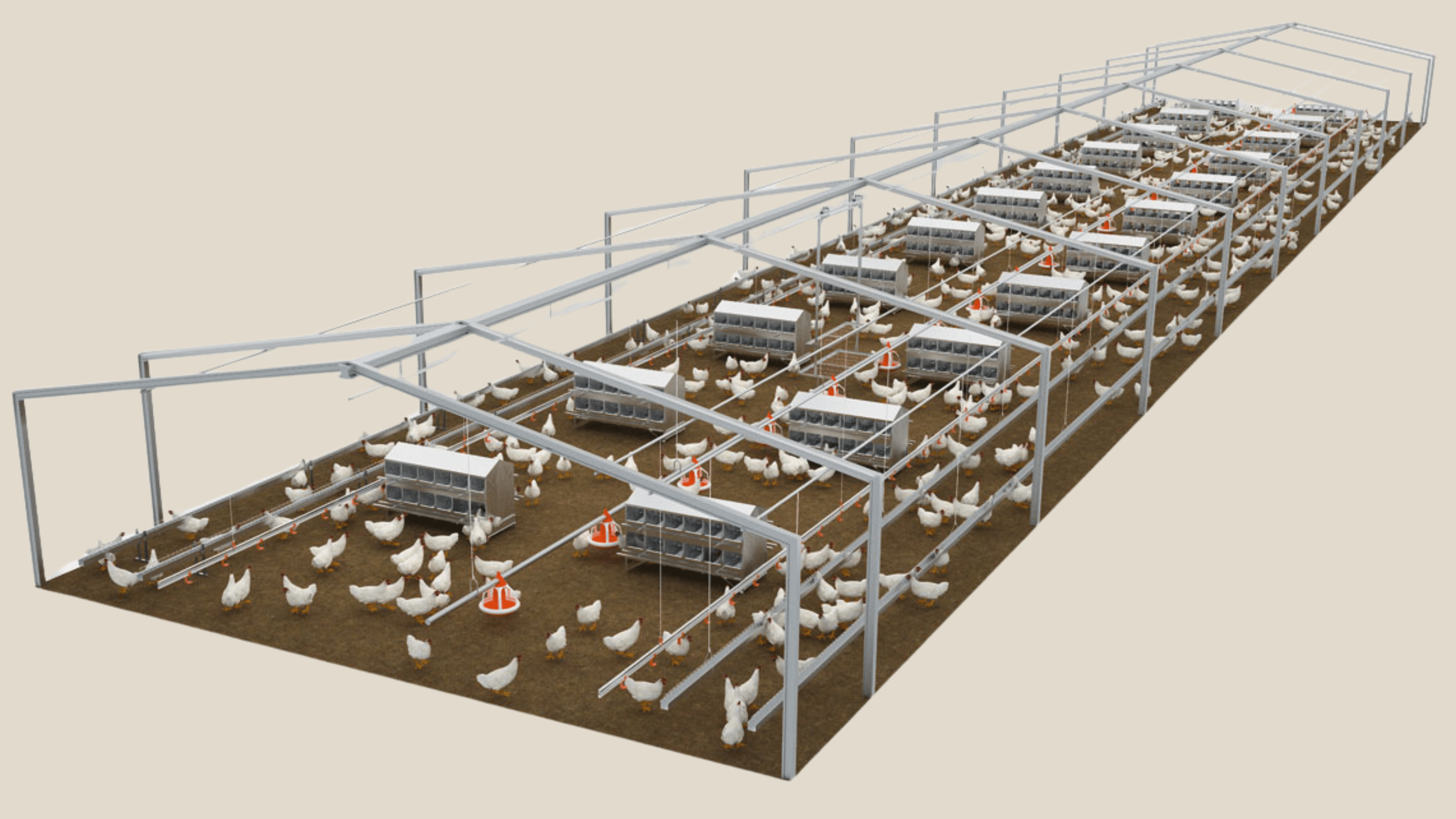

Building

Equipment

Installation and transport

An Example That Illustrates Our Skills

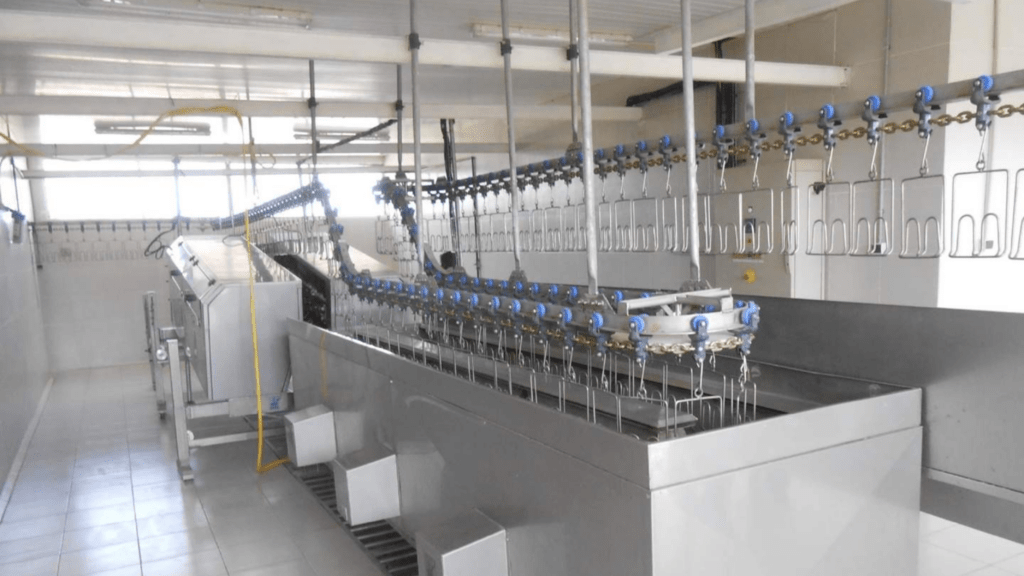

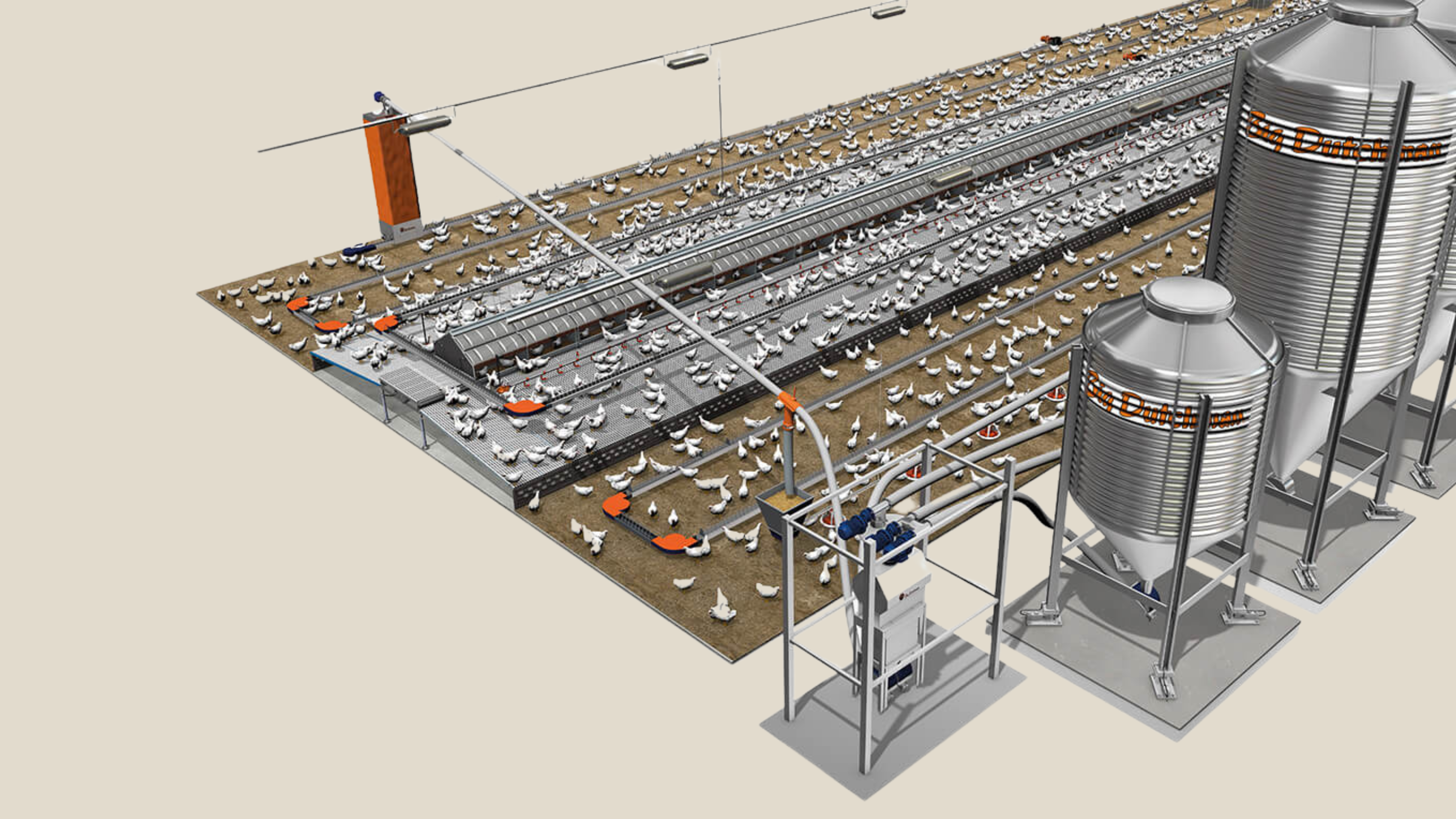

Soproda has designed a new, fully-equipped slaughterhouse in Togo, with a capacity of 2,000 to 3,000 birds per hour. This project was carried out with the aim of guaranteeing efficient, regular and high-quality production. We pride ourselves on meeting the needs of our customers in Africa, with solutions tailored to their local challenges. Visit our News page to see more examples of our work and how we help our customers achieve their goals.

A Typical Project : Explore Our Methodology

At Soproda, every project is designed down to the smallest detail to meet your exact requirements. We start with an in-depth analysis of your objectives, then design a tailored solution that optimises the environment and guarantees maximum performance. Our approach includes personalised support at every stage, from design to start-up, to ensure the success of your project. To find out how we turn your ideas into successes, visit our typical project page.

A Diversified Range to Meet All Your Needs

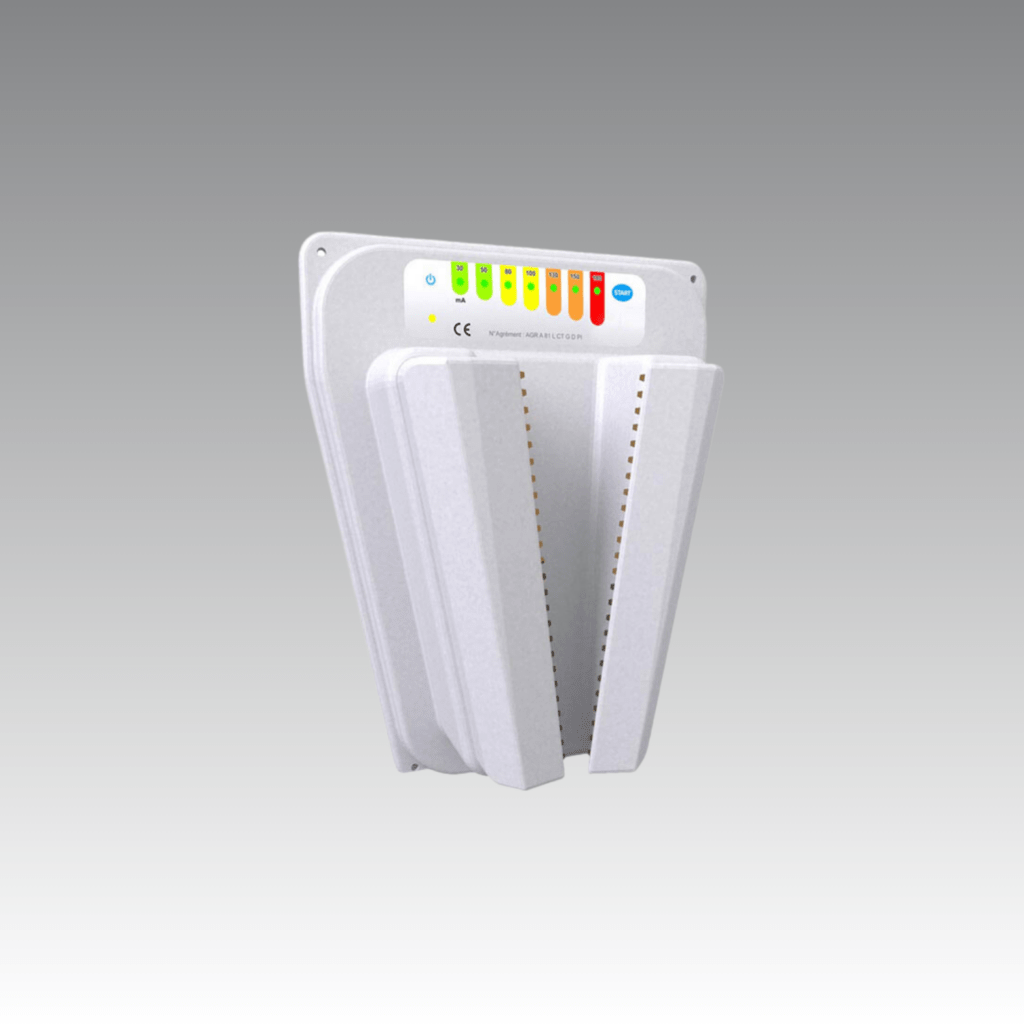

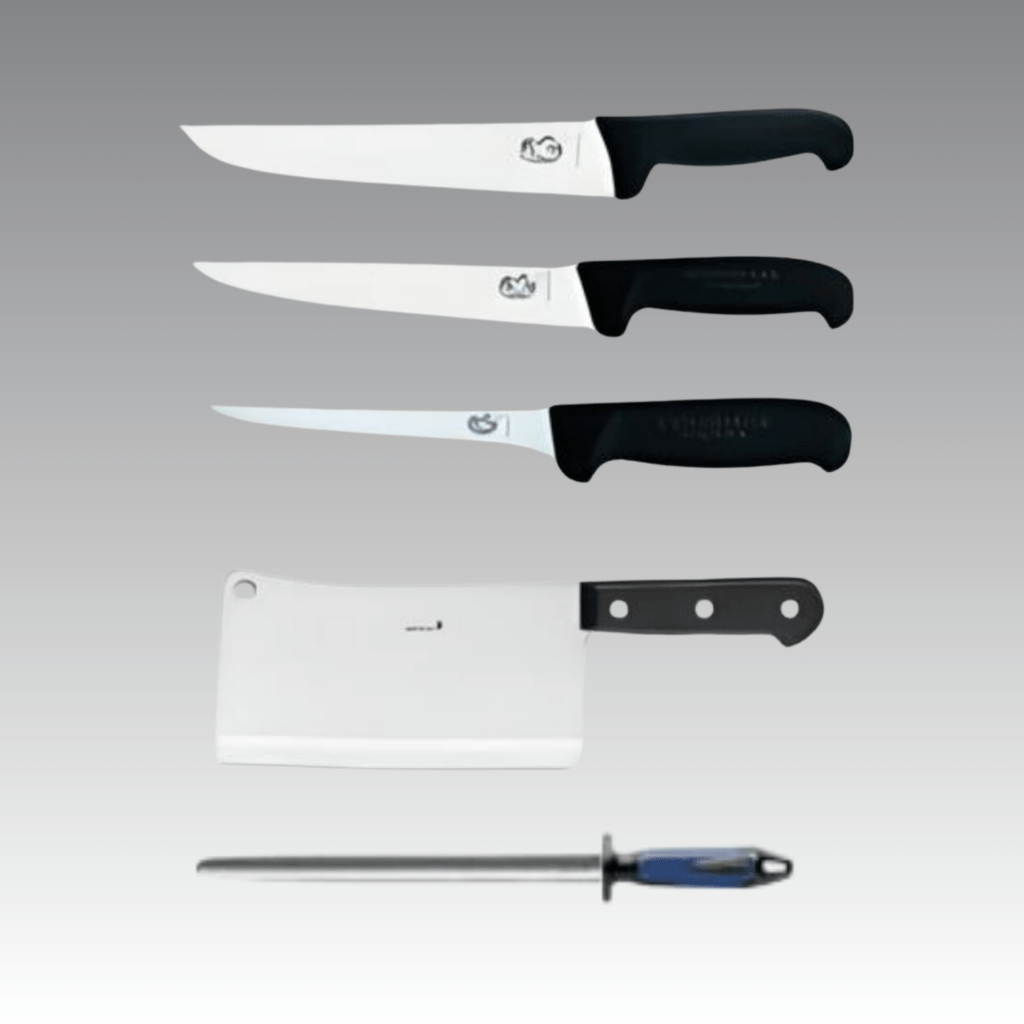

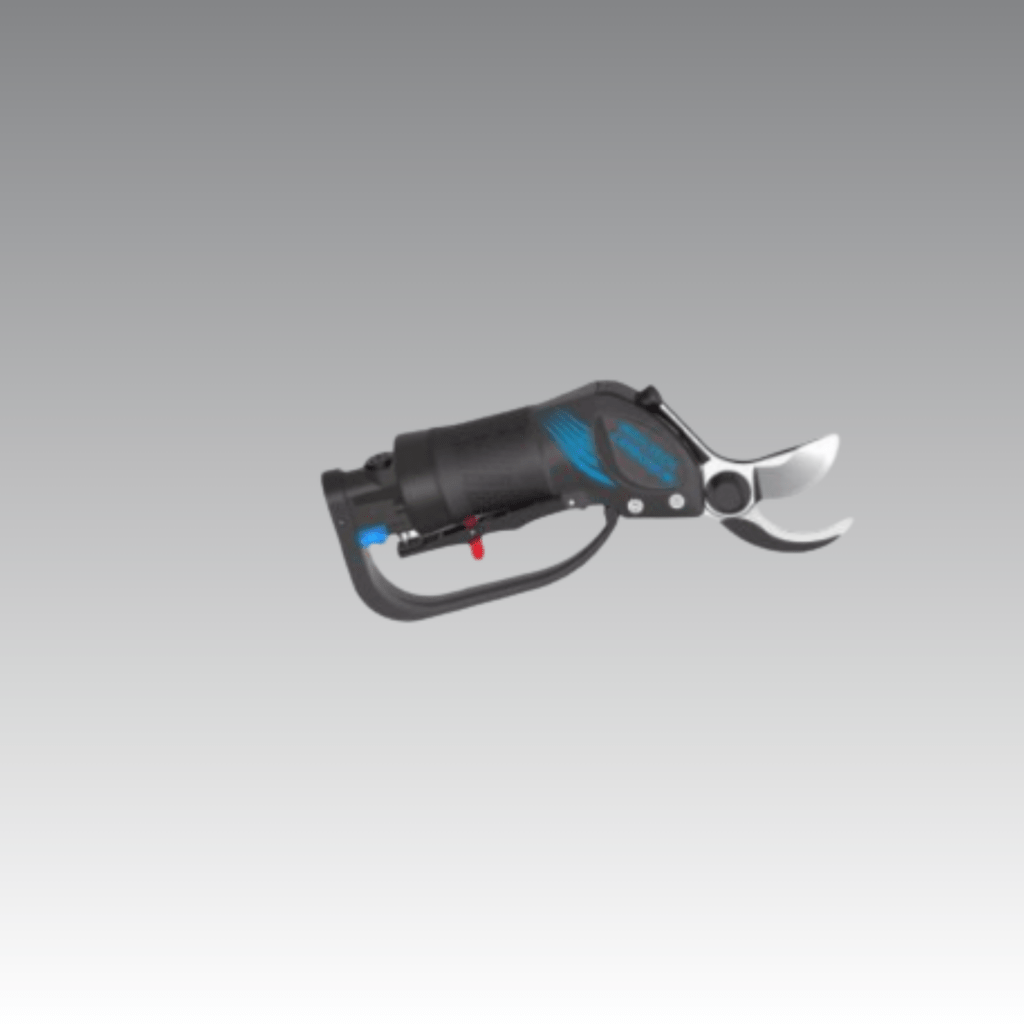

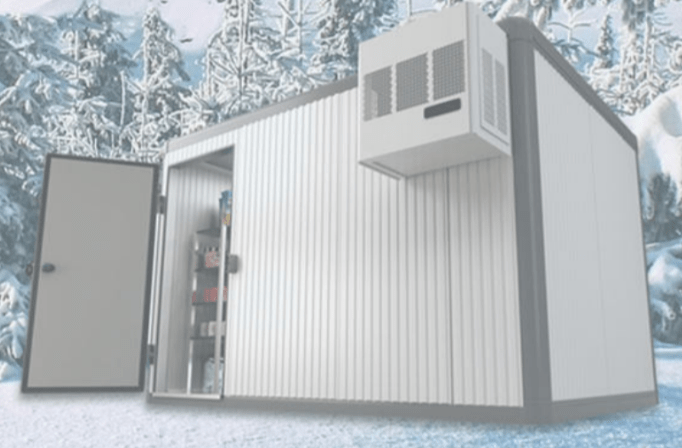

The choice of slaughter equipment is essential to maximise the efficiency of your poultry farm. That’s why we offer an online shop with a wide range of slaughtering products, including pluckers, soaking tanks, cold rooms and small equipment. This equipment is selected for its robustness and performance, guaranteeing a smooth and hygienic slaughtering process, while complying with the strictest quality standards. Our solutions are specially designed for tropical environments and incorporate the latest technologies to optimise every stage of poultry processing.