For All Your Hatching Projects

With many years’ experience, Soproda has acquired solid expertise in the field of hatching. We master every stage of the process, from egg preparation to precise management of climatic conditions. Thanks to our certified technical equipment, we can support you throughout the hatching cycle, ensuring a high success rate and optimum results.

Why Entrust Us with the Construction of Your Hatchery ?

Precision

Reliability

Performance

We know that every egg is precious. That’s why our hatching products are based on advanced technologies to guarantee an optimum hatching rate. When you choose our hatching products, you benefit from :

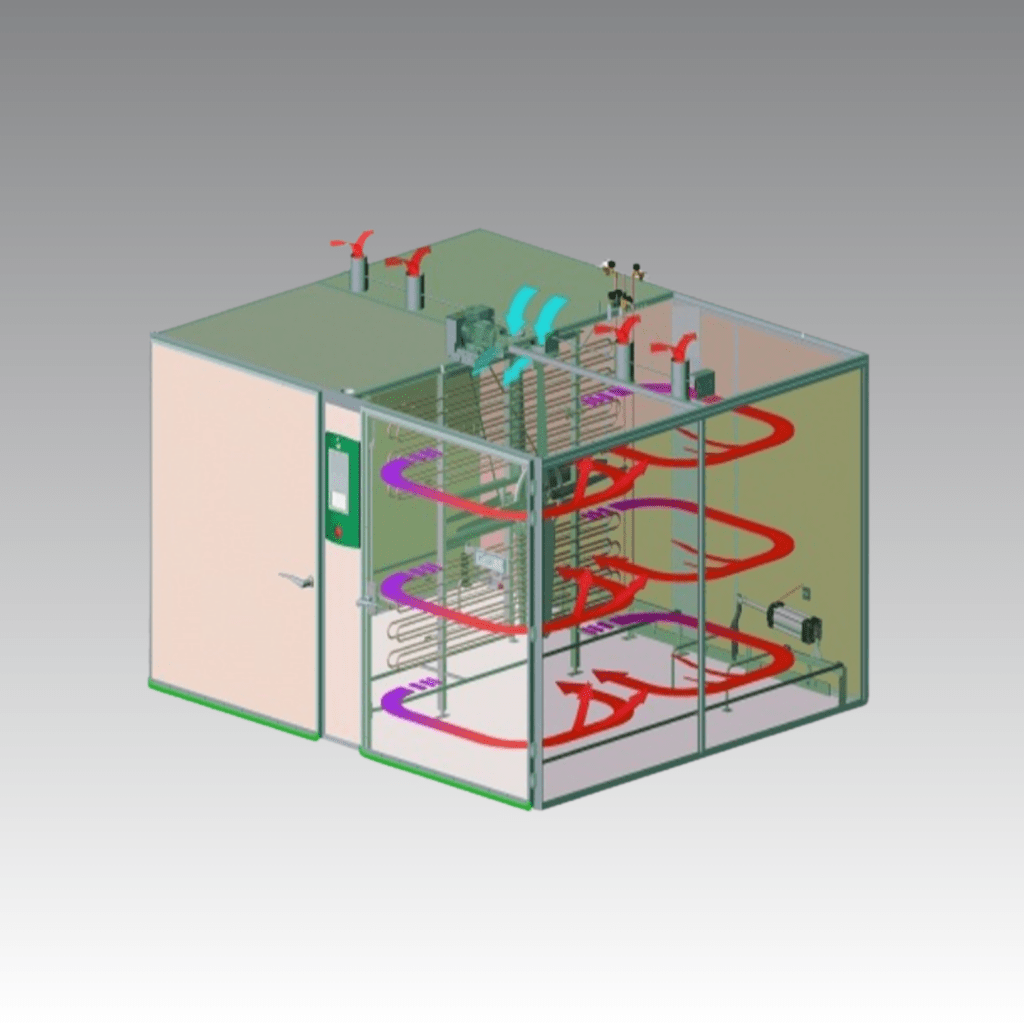

-Unrivalled accuracy : Precise control of temperature, humidity and ventilation to create the ideal incubation conditions.

-Rock-solid reliability : Robust equipment, manufactured to the highest standards, ensuring consistent, long-lasting performance.

-Constant innovation : We incorporate the latest technological advances to continually improve the efficiency of your operations.

-Personalised support : Our team of experts guides you every step of the way to optimise the use of our products and maximise your results.

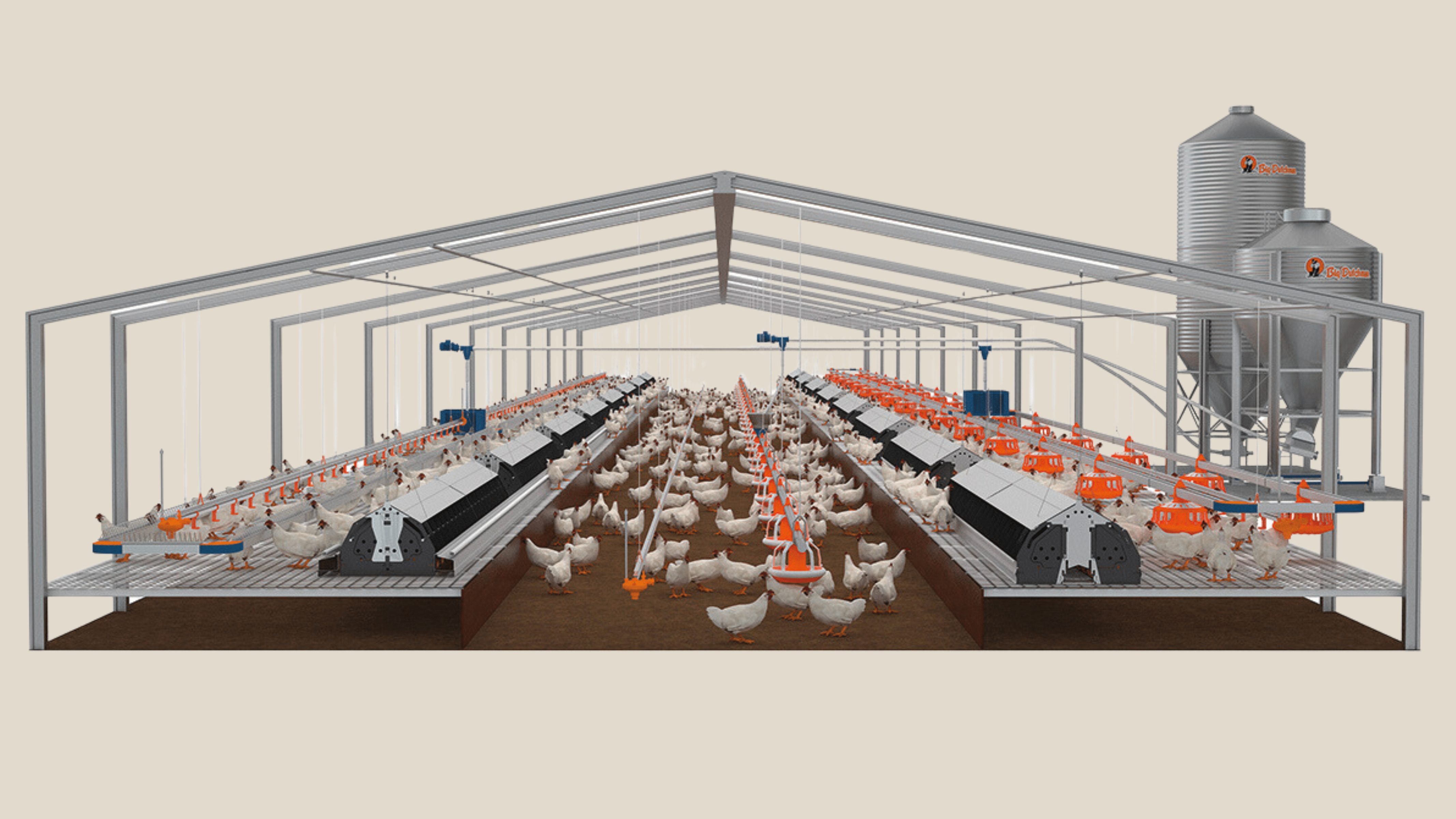

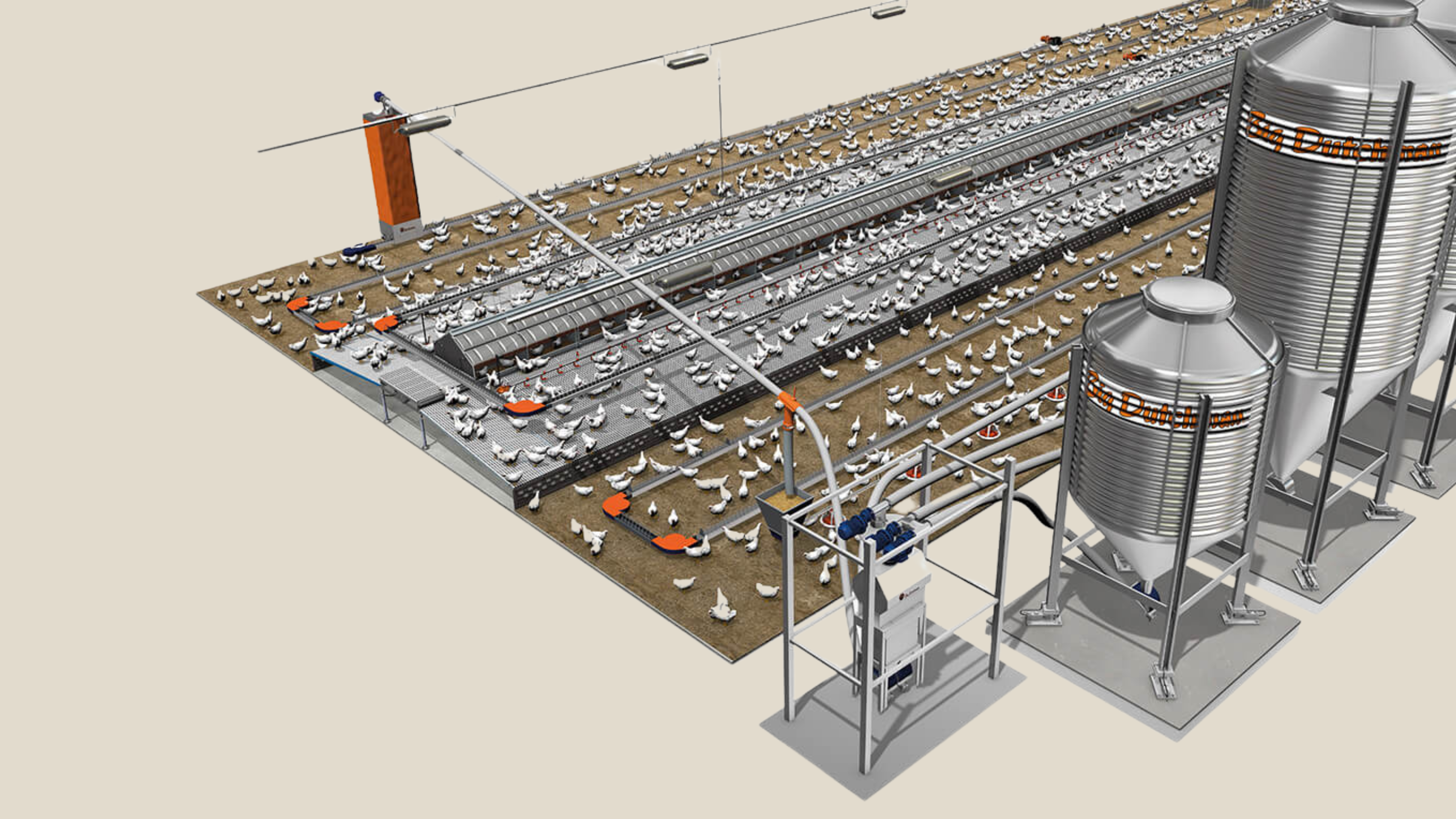

Building

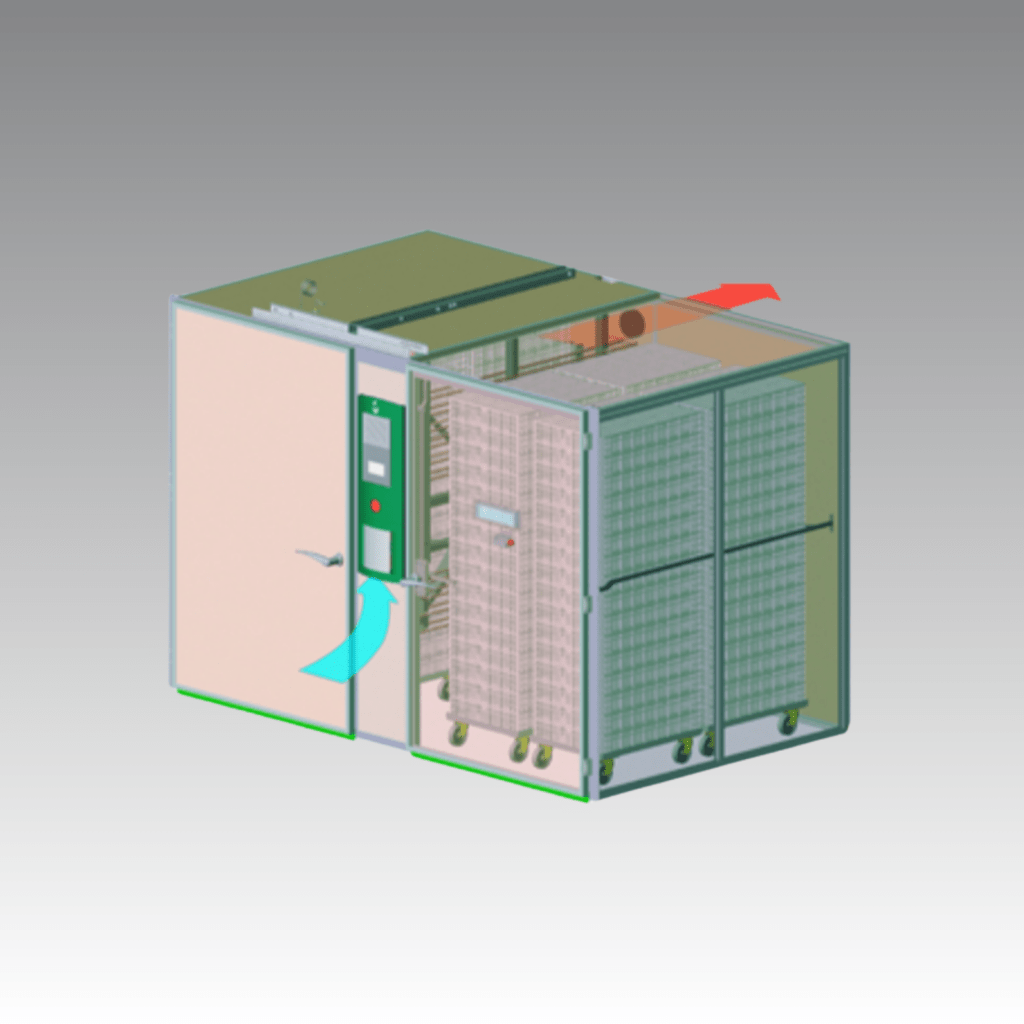

Incubation and hatching

Air conditioning and ventilation

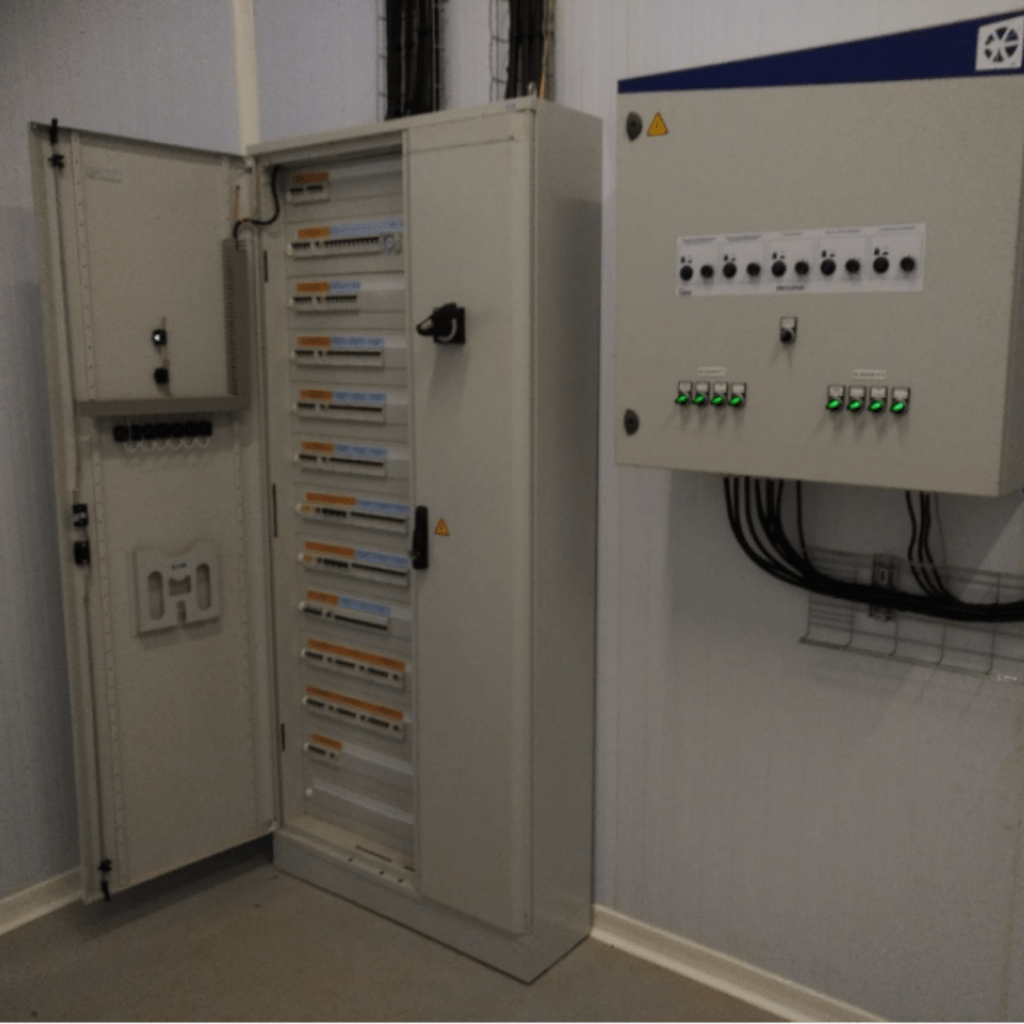

Electricity

Installation and transport

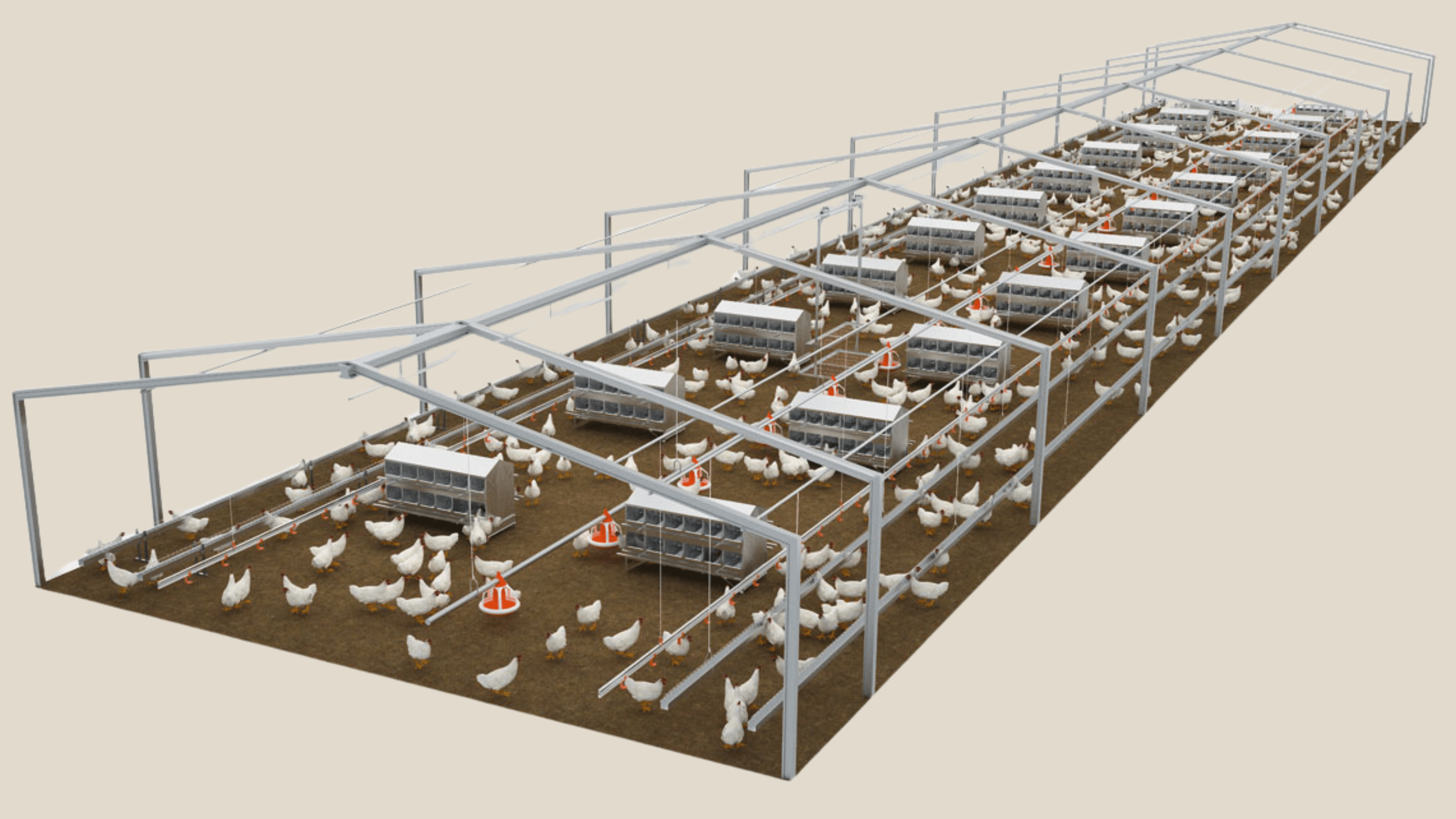

An Example That Illustrates Our Skills

Located near Kindia, the company specialises in breeding stock and the production of day-old chicks. Since 2020, it has become a reference in Guinea, with a production capacity of over 4 million chicks a year and customers in Guinea and Sierra Leone. Visit our News page to see more examples of our work and how we help our customers achieve their goals.

A Typical Project : Explore Our Methodology

At Soproda, every project is designed down to the smallest detail to meet your exact requirements. We start with an in-depth analysis of your objectives, then design a tailored solution that optimises the environment and guarantees maximum performance. Our approach includes personalised support at every stage, from design to start-up, to ensure the success of your project. To find out how we turn your ideas into successes, visit our typical project page.

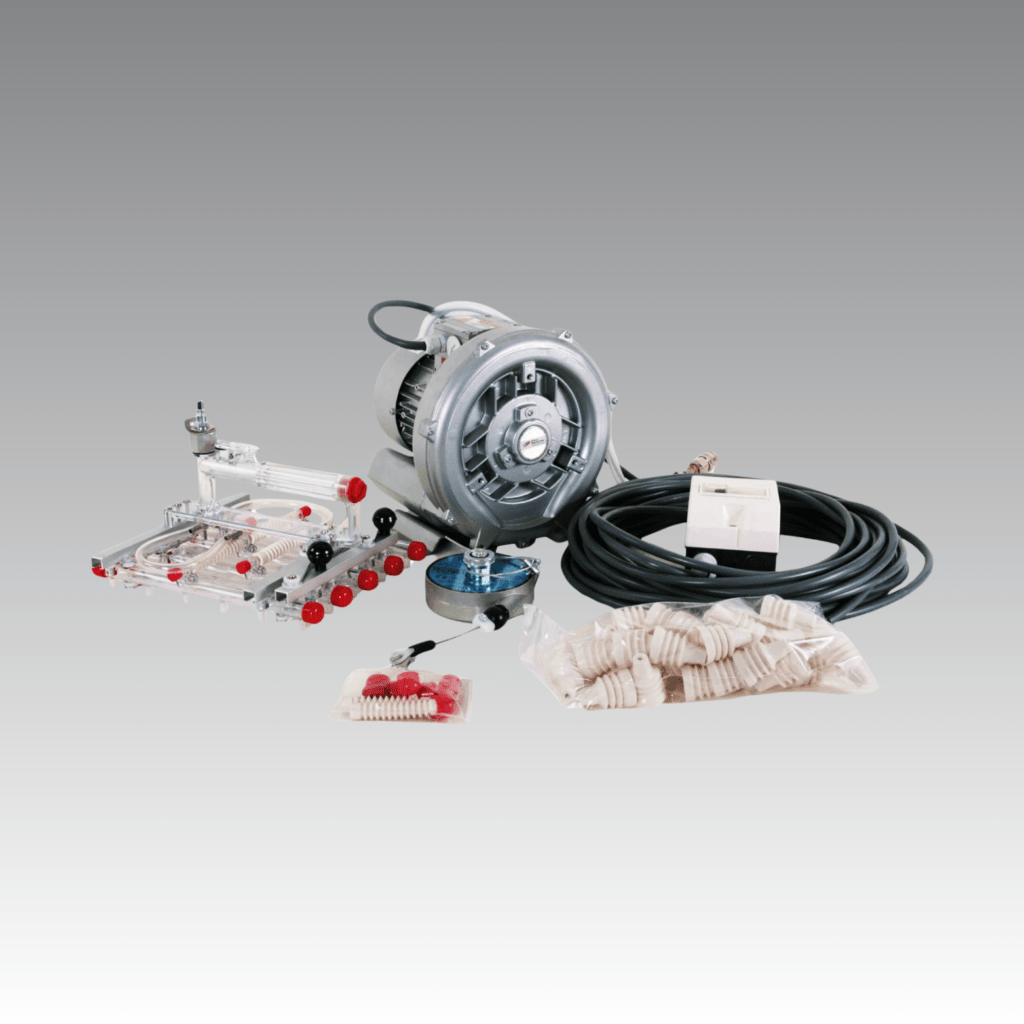

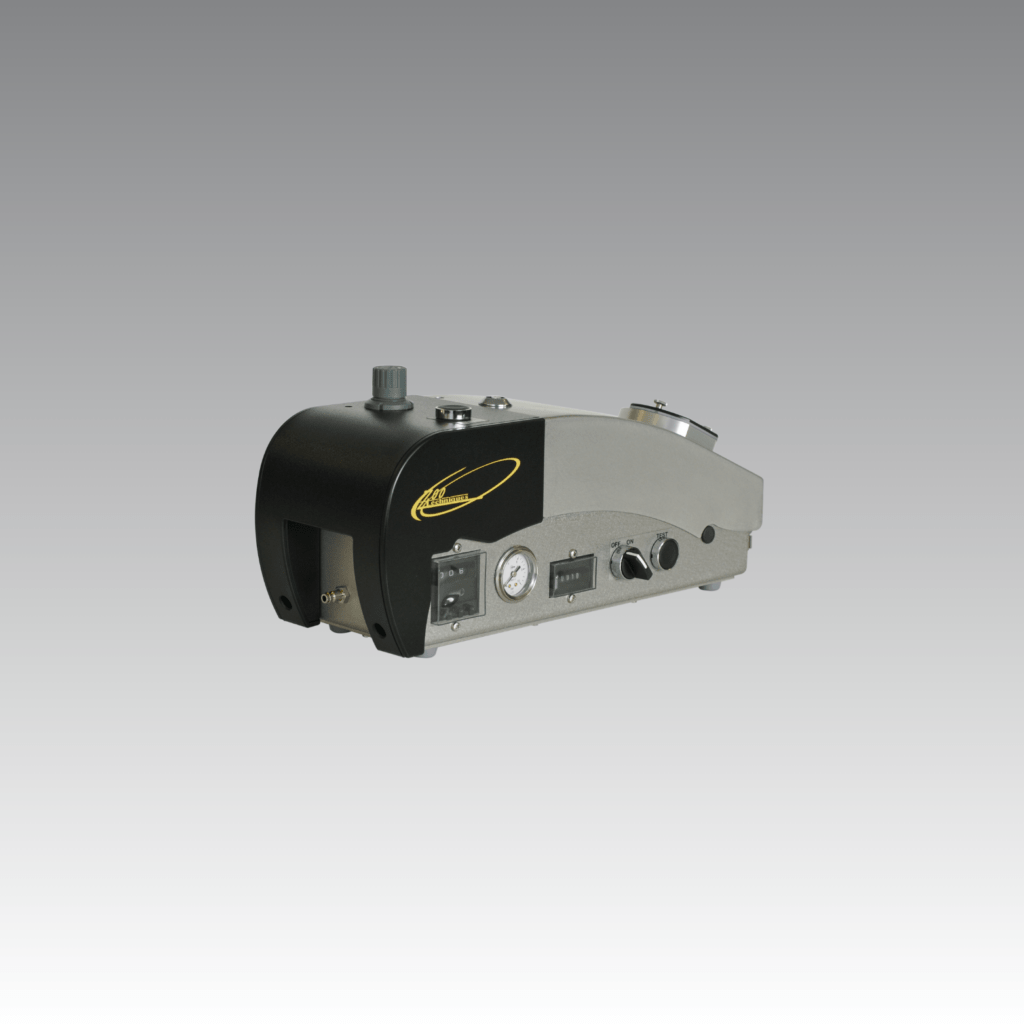

A Diversified Range to Meet All Your Needs

The choice of hatching equipment is essential to maximise the success of your poultry farm. That’s why we offer an online shop with a wide range of hatching products, including incubators, hatcheries and hatchery equipment. This equipment is selected for its reliability and performance, guaranteeing high hatching rates and exceptional durability. Our solutions are adapted to tropical conditions and incorporate the latest technologies for optimised management of incubation cycles.